Waterproofing Repairs and Structural Rehabilitation

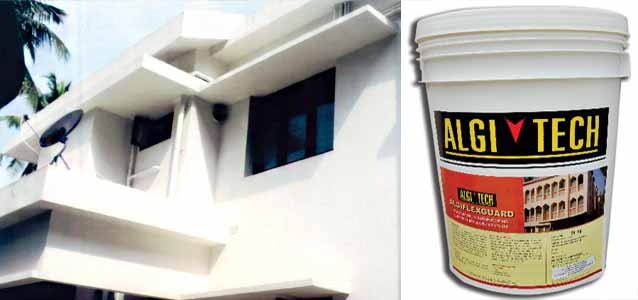

1A. ALGIFLEX GUARD

ELASTOMERIC WATERPROOFING CUM HEAT INSULATION SYSTEM.

Properties: ALGIFLEX GUARD is a single component, elastomeric, UV stable and fungus resistant coating. It bridges minor cracks when applied in sufficient thickness. It doesn’t need water curing & hence saves time & cost of labour.

Application Method: Mix ALGIFLEX GUARD with water in the ratio of 1:0.4 and apply 2 coats. When applying the coating on hot surface making the surface wet with sponge just before application of the coating improves coverage.

Coverage: About 40 square feet per Kg for 2 coats.

Download Product PDF ![]()

1B. ALGI- FLEXGUARD SPL

HIGH PERFORMANCE ELASTOMERIC WATERPROOFING CUM HEAT INSULATION SYSTEM.

Properties: ALGI-FLEXGUARD SPL is a highly elastomeric waterproofing membrane with excellent flexibility and tensile recovery and is suitable for bridging 1mm hairline cracks. The coating is highly resistant to UV light and has excellent antifungal property, hence suitable for waterproofing of exterior RCC slabs, walls, asbestos sheets, metal roof sheets etc.

Dosage: Mix ALGI-FLEXGUARD SPL with water in the ratio of 1:0.4 by volume, stir well and apply one coat of ALGI-FLEXGUARD SPL with a stiff brush. After the first coat dries (i.e., after 0.5--1 hour) apply the second coat in a direction perpendicular to the first.

Coverage: ALGI-FLEXGUARD SPL gives about 40-50 sq.ft. per kg for double coat on a fairly smooth surface.

Download Product PDF ![]()

1C. ALGI- FLEXSHIELD

HIGH PERFORMANCE ELASTOMERIC WATERPROOFING CUM HEAT INSULATION SYSTEM WITH GEOTEXTILE MAT.

Properties: ALGI-FLEXSHIELD is suitable for RCC slabs, wall, asbestos sheets, China mosaic, plastic and metal roof sheets. This product has excellent adhesion, and is suitable for difficult to bond surfaces and during labour shortages as it has very low application cost. The coating is highly resistant to UV light and has excellent antifungal property.

Coverage: About 11-12.5 Sq. ft/kg for 4 coats with the geotextile mat on fairly smooth surface.

1D. ALGI- FLEXSHIELD SP

HIGH PERFORMANCE ELASTOMERIC WATERPROOFING CUM HEAT INSULATION SYSTEM WITH GEOTEXTILE MAT.

Properties: ALGI-FLEXSHIELD SP is suitable for RCC slabs, wall, asbestos sheets, China mosaic, plastic and metal roof sheets. This product has excellent adhesion, and is suitable for difficult to bond surface. The coating is highly resistant to UV light and has excellent antifungal property.

Coverage: About 11-12.5 Sq.ft/kg for 4 coats with the geotextile mat on fairly smooth surface.

Download Product PDF ![]()

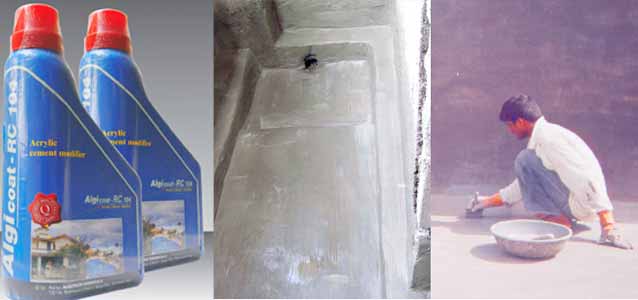

1E. ALGICOAT RC 104

ACRYLIC POLYMER ADMIXTURE FOR WATER PROOFING SYSTEM.

Properties: ALGICOAT RC-104 coating has good breathing capacity and UV stability and hence can be applied on moist surface. It is suitable for waterproofing of terraces, bathrooms, masonry walls, water-tanks, basements etc.

Application Method: Mix 1.5 part of ALGICOAT RC-104 with 1.8 parts by volume of cement and apply 2 coats by brush on moist and cleaned surface. Needs 7 days of water curing.

Coverage: 1 litre of ALGICOAT RC -104 gives 25 sq ft coverage.

Download Product PDF ![]()

1F. ALGICRETE

ACRYLIC POLYMER FOR CRACK-FILLING AND FOR MODIFYING CEMENT MORTAR/SCREED CONCRETE.

Application Areas: ALGI CRETE is used for crack filling by mixing with white cement. By using as an admixture in cement mortars. ALGICRETE is also used for repair mortars.

Method of Usage: For crack filling mix ALGI CRETE with white cement in the ratio of 1:2 and in case of cement mortar use 3--6kg per bag of cement in cement sand 1:3 mortar.

1G. ALGICRETE GP

ACRYLIC POLYMER FOR WATERPROOFING COATING.

Application Areas: ALGICRETE GP is used for waterproofing repairs in case of bathrooms and for sandwitch layer waterproofing.

Method of Usage: Mix with cement in the ratio of 1:1.75 and apply 2 coats

Coverage: 22-26 Sqft. per Litre

1H. ALGICOAT EPX-W

WATER BASED EPOXY FLOOR COATING.

Properties: ALGICOAT EPX-W coating is easy to clean and is resistant to oil, mild acids and alkalies. It reduces fungus/algae growth in water tanks. It is available in different colours. The product can be thinned with water.

Application Method: The concrete surface should be free from loose particles, dust, oil, grease or any other chemical deposits. Clean concrete surface using a wire brush. First mix ALGICOAT EPX W resin & hardener in 1:1 ratio to obtain an uniform consistency. Then add 1 part water so that resin : hardener : water ratio is 1:1:1. Mixing all three components simultaneously will prevent product from setting and should be avoided.

Coverage: 40 sq. ft. per Kg for 2 coats.

Download Product PDF ![]()

1I. ALGILATEX

SBR LATEX POLYMER ADDITIVE FOR POLYMER MODIFIED CONCRETE/ MORTAR.

Properties: Makes cement mortar waterproof, flexible and reduces its w/c ratio. Also improves tolerance for poor curing practices.

Application Areas: ALGI LATEX is used as a polymer additive for cement mortar in structural repairs and ALGI LATEX is mixed with cement and the slurry obtained is used as an anticorrosive coating.

Application Method: ALGILATEX should be mixed with water and added to cement mortar. Dosage: 3-6 kgs per 50 kg cement.

Download Product PDF ![]()

1J. ALGILATEX SP

POLYMER ADDITIVE BASED ON SBR LATEX FOR POLYMER MODIFIED CONCRETE/MORTAR.

Properties: ALGILATEX SP improves the mechanical properties such as flexure and tension. It also improves the water resistance of cementatious mixes. It is a highly economical bonding agent having excellent bonding strength.

Coverage: As a bond coat use. Algi Latex SP; Water; Cement in the ratio of 1:1.8:4 by volume gives 100-120ft /kg for Polymer Modified Mortar: 200 ft²/mm thickness, for Polymer Modified Concrete: 30 to 40 Kg/m³ volume.

1K. ALGIMICROCRETE

NON SHRINK CEMENTATIOUS MICRO CONCRETE FOR STRUCTURAL REHABILITATION

Properties: ALGIMICROCRETE is an ideal micro concrete for structural strengthening of columns, beams etc., by encasement. Algimicrocrete is compatible for use with different grades of concrete and can be used for encasement of sections which are up to 100mm. Larger sections can be built up with Algimicrocrete mixed with 5-12mm aggregates in the proportion of 50 -100% by weight.

Method of Usage: Mix ALGIMICROCRETE with water in the ratio of 0.165 and pour.

Coverage: 1.8 Kg. per litre volume to grouted.

Download Product PDF ![]()

1L. ALGIPLUG WELL

GROUT ADDITIVE FOR PLUGGING VOIDS IN CONCRETE.

Properties: Provides extension of setting time and very high water reduction. Also reduces settling of grout. Helps grout travel deep into voids in concrete.

Application Method: Mix in the ratio of 1 litre of ALGIPLUG WELL per 50 Kg cement and 50-60 Litre water. Grout this mixture into the structure.

Download Product PDF ![]()

1M. ALGIINJECTIONGROUT EPX

IT IS A INJECTION GRADE MOISTURE INSENSITIVE SOLVENT FREE, LOW VISCOSITY EPOXY GROUT FOR PRESSURE GROUTING.

Properties: It has very high flow. Compressive strength achieved is 800 kg/cm2. Water absorption is less than 0.1%. Adhesion strength is more than 30 kg/cm2 . Bonds almost any material. It gives very high chemical and abrasion resistance.

Application Method: Highly suitable for critical water proofing repairs and grouting of railway and road bridges for structurally strengthening work & also for rehabilitation of earth quake / flood / fire damaged structures. Application Method: Mix resin and hardener to uniform consistency & inject into cracks under pressure

Coverage: For 1 litre of volume to be grouted 1k.g. grout is needed.

1N. ALGIGROUT ADMIXTURE SP

NON SHRINK SUPER PLASTICIZING GROUTING ADMIXTURE.

Properties: Improves flow retention, impermeability and also makes grout travel further into voids.

Application Method: ALGIGROUT ADMIXTURE SP should be mixed with cement grout.

Dosage: 225gm per bag of cement.

Download Product PDF ![]()

1O. ALGICOAT ACRYLIC

ACRYLIC BASED COLOURED/COLOURLESS DECORATIVE AND PROTECTIVE WATER PROOFING SEALER WITH GLOSS EFFECT.

Properties: M ALGICOAT ACRYLIC is a coloured or colourless glossy/mat waterproofing coating suitable for vertical/ sloping surfaces, clay tiles, brick and laterite stones etc.

Application Method: Apply 2 coats of ALGICOAT ACRYLIC by brush on a clean & totally dry surface. If applied on moist surface the coating will peel off. Apply ALGICOAT ACRYLIC coating during morning or in the evening to get good coverage during summer.

Coverage: 40sq. ft. per litre for 2 coats.

Download Product PDF ![]()

1P. ALGIINSULEX SP

A HIGH PERFORMANCE HEAT INSULATION SYSTEM.

Properties: Fungus Resistant coating which reduces heat within the building. Reduces or eliminates airconditioning cost. The coating is highly resistant to damage due to scrubbing, abrasion, and UV Light. Suitable for RCC Slabs, asbestos, metal roofing sheets etc

Application Method: Clean the surface with wire brush and wash with water. Dilute Algiinsulex SP with water in 1:0.4 ratio & apply 2 coats by brush. To get good coverage during summer, wet the surface by sponging just before application of the coating .

Coverage: About 40 sq. ft. per Kg for double coat.

Download Product PDF ![]()

1Q. ALGISIL GUARD

DEEP PENETRATING TRANSPARENT WATER PROOFING AND WATER REPELLENT SEALER.

Properties: ALGISIL GUARD is a silane siloxane based deep penetrating chemical with excellent water repellency and water proofing quality. It is supplied in concentrated form and has to be diluted in water in the ratio of 1:7 by volume before use. When applied, it penetrates deep beneath the surface in 3 to 5 mm depth to line pores with a thin water- repellant coating. Diluted product can also be used for grouting (without cement) to prevent dampness rising through plinthlevel in masonry. Being water based it is safe to store and to use in closed areas.

1R. ALGIFIBRE

POLYPROPYLENE FIBRE FOR CONCRETE/MORTAR REINFORCEMENT.

Properties: ALGIFIBRE is a high performance modified polypropylene engineered fibre designed specifically for secondary reinforcement of concrete. ALGIFIBRE disperses in the concrete mix when added at the batching plant or at the job site to form a true 3 - dimensional reinforcement network which reduces cracking and increases the strength. Algifibre is made of poly propylene, it doesn't dissolve in alkaline solution like polyester and this alkali stable (Cement is highly alkaline) and gives long lasting benefit.

Dosage: Add at the rate of 120gms per bag of cement. Soak ALGIFIBRE 120 gm in 3to 4 litre water for 3-5 minutes and then add to premixed cement sand mortar.

Download Product PDF ![]()

1S. ALGICRYSTALLEX

CRYSTALLINE WATERPROOFING COATING FOR NEGATIVE SIDE WATERPROOFING

Properties: ALGICRYSTALLEX is a crystalline coating that can be applied for waterproofing of bathrooms, basements, water tanks, swimming pools and masonry. It can be applied for both negative and positive sides and on moist surfaces.

Application Method: After the surface preparation, apply the first coat made up of 1 part of ALGICRYSTALLEX and 0.5 part of water by volume. The mix should be well stirred. Apply the second coat after the first coat has dried for 1--2 hours. The coating should be cured by spraying water for 3--5 days. The coating should not be cured by water ponding. After 5 days it should be allowed to air dry for 2, 3 weeks.

Coverage: 70-80 running feet per Kg.

Crack and Expansion Joint Sealants

2A. ALGISEAL ACRYLIC

A SINGLE COMPONENT ACRYLIC SEALANT FOR ROOF CRACKS.

Properties: Single component ready to use, paintable acrylic sealant. It is suitable for cracks with movement of +/- 10% (expansion and contraction). Available in both plastic containers and in cartridges.

Application Method: Clean and widen the cracks to 5mm X 5mm wide section using a marble cutter and fill it with ALGISEAL ACRYLIC. After drying, fill the crack again. The ALGISEAL ACRYLIC must be filled at least twice. 2 to 3 applications are needed to get a level surface. For external cracks, the sealant should be covered with ALGICOAT RC 104 or Algiflexguard.

Coverage: 50 running feet per Kg.

Download Product PDF ![]()

2B. ALGISEAL ACRYLIC GP

ACRYLIC SEALANT FOR WALL CRACKS.

Properties: ALGISEAL ACRYLIC GP is a single component, ready to use paintable, flexible, acrylic sealant with reduced shrinkage. It is suitable for cracks with movement of +/-7%. ALGISEAL ACRYLIC GP can be applied as crack filler for interior walls and window joints.

Application Method: Clean and widen the crack to 5mm X 5mm wide section using a marble cutter. Fill up the crack with sealant and after drying fill again for the second time.

Coverage: 1 kg covers approximately 30 running feet for 4mm wide X 4mm deep wall cracks.

Download Product PDF ![]()

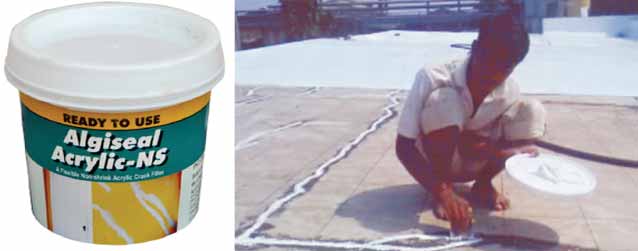

2C. ALGISEAL ACRYLIC NS

A LOW SHRINKAGE ACRYLIC SEALANT FOR CRACK FILLING OF INTERIOR WALLS.

Properties: ALGISEAL ACRYLIC GP is a single component, ready to use paintable, flexible, acrylic crackfiller with with very low level of shrinkage. It is suitable for cracks with movement of +/-5%. It can be applied as a crackfiller for internal walls and window frames.

Application Method: Clean and widen the crack to 4mm X 4mm wide section using a marble cutter. Fill the crack with the sealant and after drying fill the crack again for the second time.

Coverage: ALGISEAL ACRYLIC NS 1 Kg covers approximately 40 running feet for 4mm X 4mm deep wall cracks.

Download Product PDF ![]()

2D. ALGISEAL PSD

TWO COMPONENT POLYSULPHIDE SEALANT FOR EXPANSION JOINT & EXTERNAL CRACK FILLING.

Properties: ALGISEAL PSD is a highly flexible, UV Light stable, chemical & solvent resistant Polysulphide sealant. It is a polysulphide sealant for filling of expansion joints with maximum of +/- 25% movement.

Application Method: Clean and allow the joint to dry. Apply ALGISEAL PS primer. Mix ALGISEAL PS resin & hardener to uniform consistency & apply into the joint.

Coverage: 20ft/kg for 12mm wide X 6mm deep joint. 9ft. / Kg. for 18mm wide X 9mm deep joints. 5ft. / kg. for 24mm wide X 12 mm deep joints. Note: For horizontal and narrow joints width Algiseal PS pourable grade of polysulphide sealant can be used.

Download Product PDF ![]()

2E. ALGISEAL PS-P (Pourable)

TWO COMPONENT POLYSULPHIDE SEALANT FOR NARROW EXTERNAL CRACK FILLING & NARROW INDUSTRIAL FLOOR JOINTS.

Properties: ALGISEAL PS-P is highly flexible, UV Light stable, chemical & solvent resistant Polysulphide sealant. It is easy to use as it has low viscosity. It is recommended for narrow joints and for exterior waterproofing by crack filling. It is a polysulphide sealant for filling of expansion joints with maximum of +/- 25% movement.

Application Method: Clean and allow the joint to dry. Apply ALGISEAL PS primer. Mix ALGISEAL PS-P resin & hardener to uniform consistency & apply into the joint.

Coverage: 20ft/kg for 12mm wide X 6mm deep joint. 9ft. / Kg. for 18mm wide X 9mm deep joints. 5ft. / kg. for 24mm wide X 12 mm deep joints. Note: For horizontal and narrow joints width ALGISEAL PS-P pourable grade of polysulphide sealant can be used.

2F. ALGISEAL PUR

SINGLE COMPONENT POLYURETHANE SEALANT FOR EXTERNAL CRACK FILLING & INDUSTRIAL FLOOR JOINTS.

Properties: ALGISEAL PUR is a single component sealant recommended for external crack filling and also for expansion joints. Algiseal PUR is a single component sealant with very high tensile strength and movement capability. It has excellent bonding strength and doesn't require primer application and is ready to use and very easy to apply. The product adheres very well to metal and concrete surface. Always use Algiseal PS for external expansion joints subjected to sunlight and moisture.

Coverage: For 20 mm width and 12 mm depth-6 feet/kg, for 20mm width and 20 mm depth (for main slab waterproofing) = 3.5 feet/kg.

2G. ALGICRACK FILLER

ECONOMICAL CEMENTATIOUS CRACK FILLER.

Properties: Recommended for filling wide rigid cracks i.e., non moving cracks on internal walls. It is non shrink. Requires single application.

Application method: Clean and widen the crack, mix ALGICRACK FILLER and water in 3:1 proportion & fill up the crack using putty blade. Mix Algicrack Filler with Algicrete or Algilatex where improved performance & flexibility is required.

Bonding Agents

3A. ALGIBOND EPOXY 202

EPOXY BASED MOISTURE INSENSITIVE THIXOTROPIC BONDING AGENT

Properties: Excellent adhesion to concrete, screed, mortar etc. Application: Suitable for bonding joints between old to new concrete.

Application Method: Use entire quantity of resin and hardner & mix well and apply a single thick coat by brush over clean and dry surface. In case of part mixing only weight batching should be adopted. Immediately place and compact fresh concrete or mortaron it.

Coverage: 30 running feet per Kg. for a 4 inch thick concrete slab joint or 20ft2/kg for application on concrete slab.

Download Product PDF ![]()

3B. ALGIBOND EPX202 ULTRA FS

FAST SETTING EPOXY BASED MOISTURE INSENSITIVE

THRIXOTROPIC BONDING AGENT (Sets within 30 minutes)

3C. ALGIBOND LATEX

SBR LATEX BASED BONDING AGENT.

Properties: For improving adhesion between cement mortar & concrete in patch repairs, plastering, screed concrete etc and also for bonding joints between old to new concrete for old slabs use Algibong EPX 202

Application Method: Mix ALGIBOND LATEX with fresh cement in the ratio of 1:1.5 by volume and apply one coat of mixed material by brush over the cleaned surface. Immediately pour fresh concrete or mortar over it and compact.

Coverage: 45 Sq. ft. per litre.

Download Product PDF ![]()